Industrial Automation

Industrial Automation Solutions by Intelysol

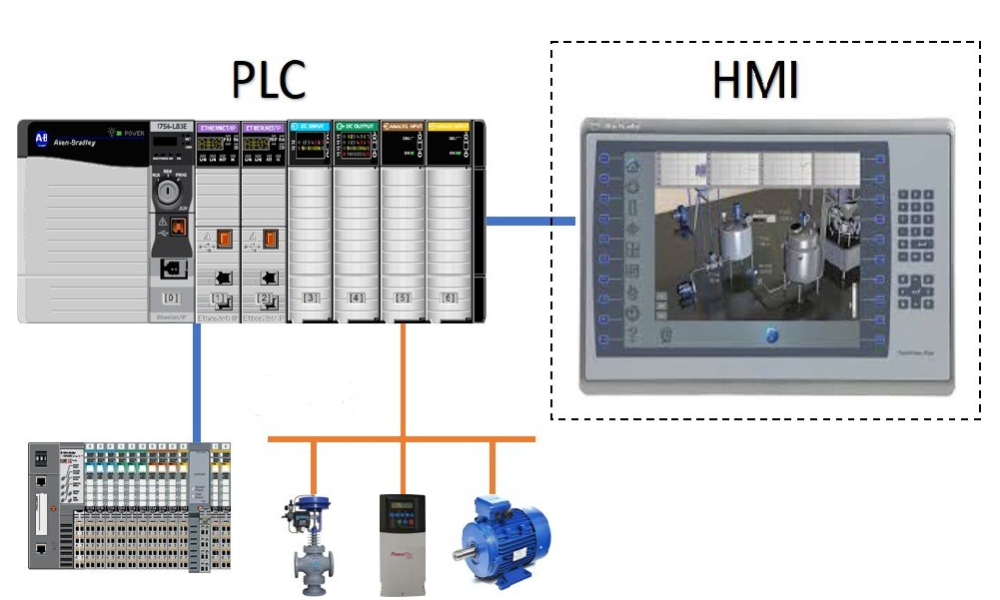

Welcome to Intelysol’s Industrial Automation solutions, designed to boost productivity, reduce downtime, and optimize operations. We specialize in PLC, HMI, and smart automation technologies, delivering scalable and cost-effective systems tailored to your needs. Enhance efficiency and embrace Industry 4.0 with Intelysol. Contact us today to learn how we can transform your operations.

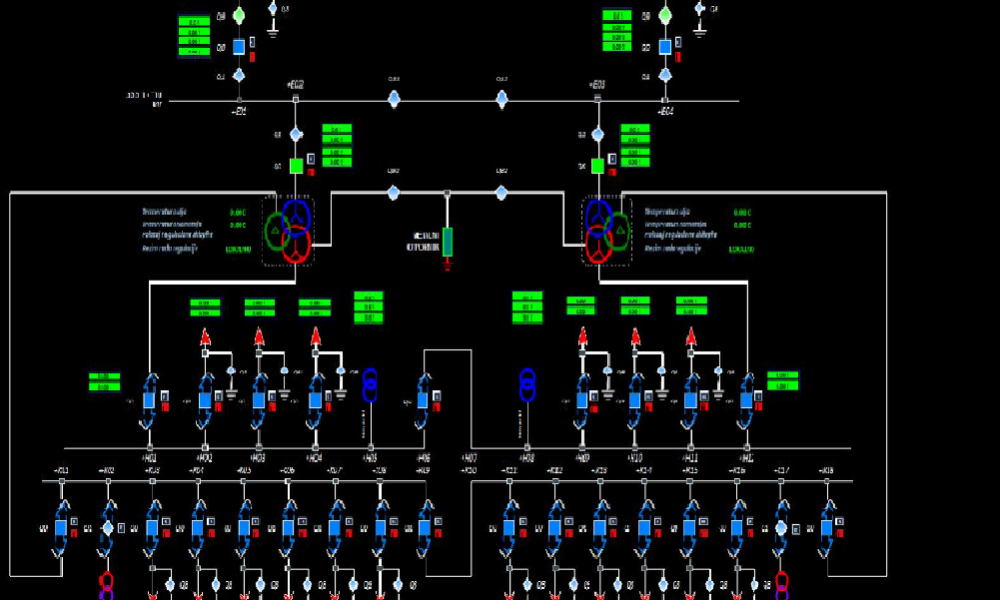

SCADA Industrial Automation

Loom Monitoring

Efficiency Boards

Temperature & Humidity

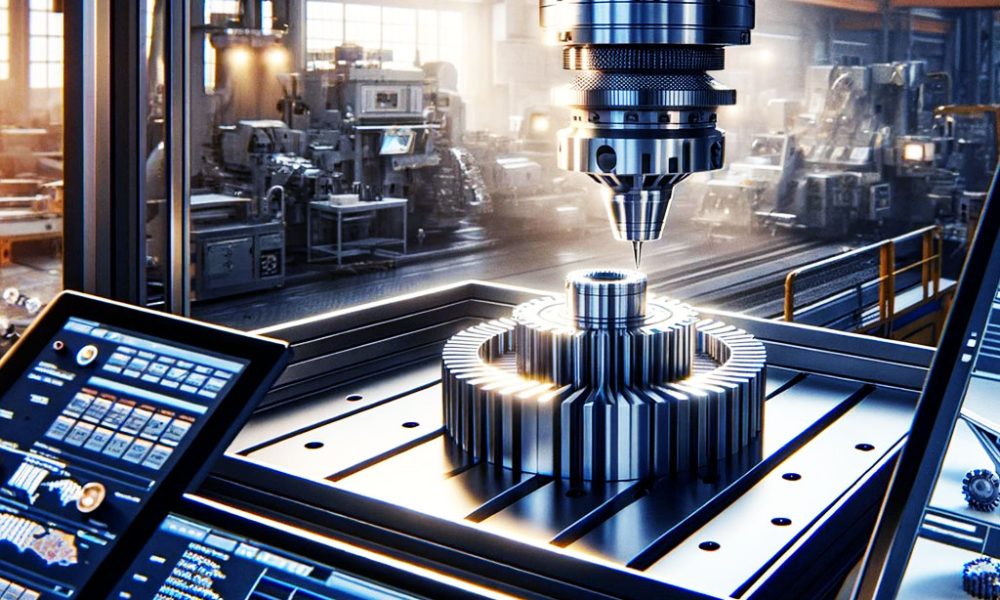

CNC Machines

PLC & HMI Integration